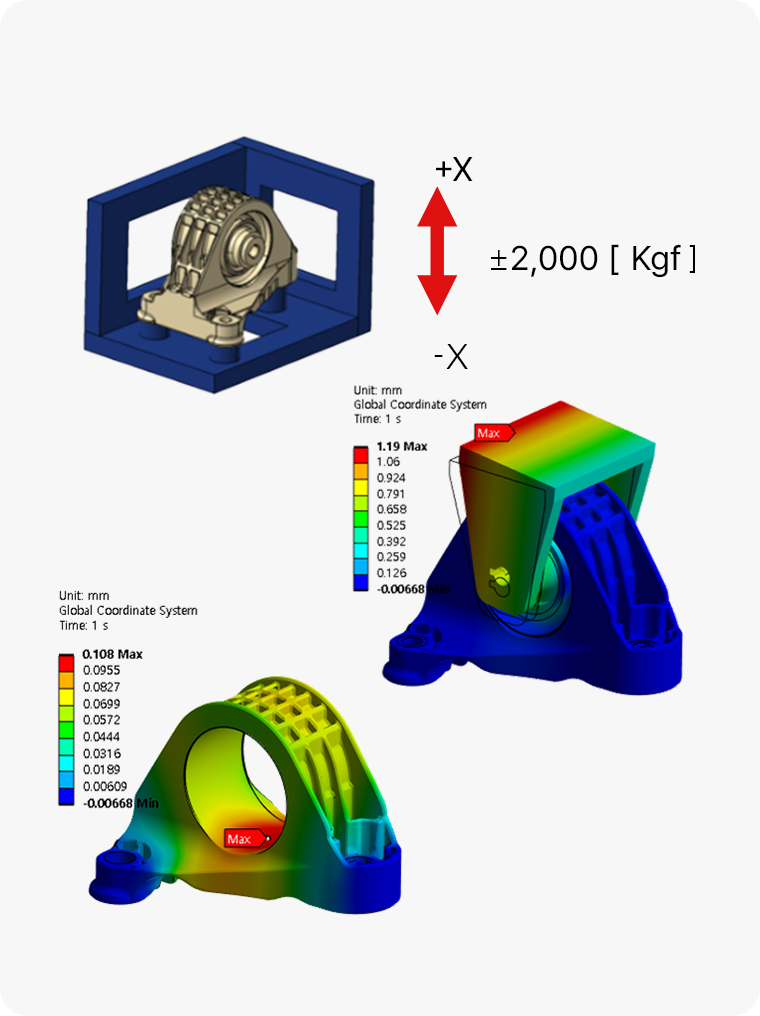

Static Structural Analysis

Strength evaluation of products through static structural analysis

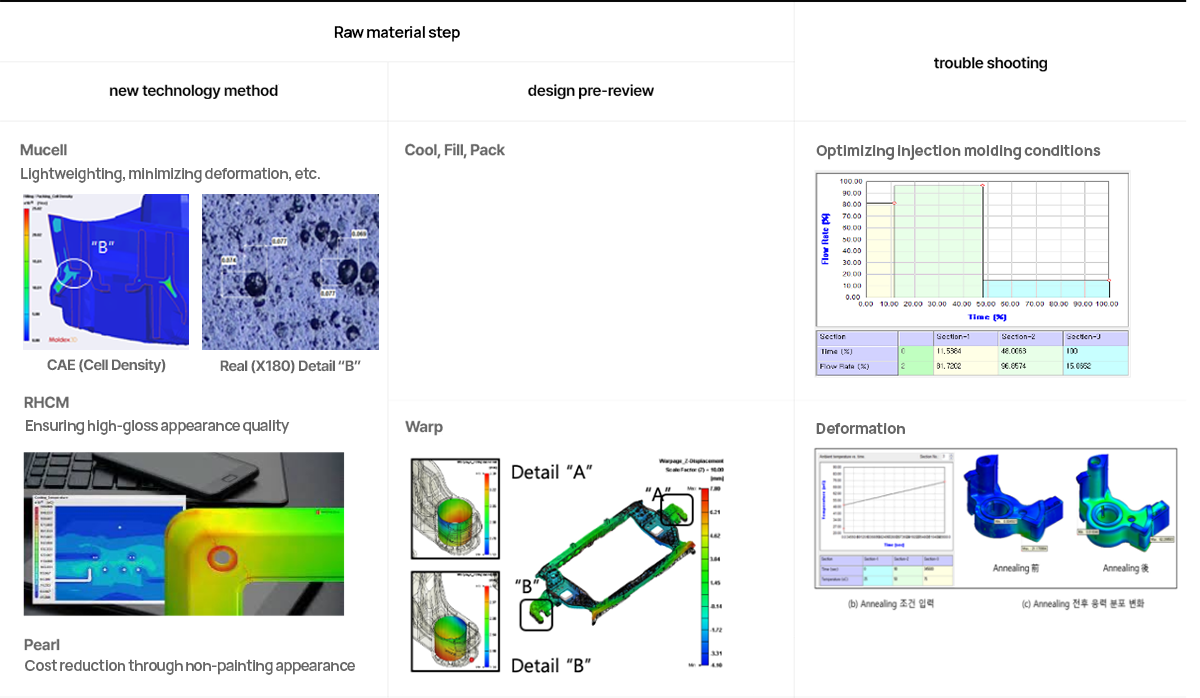

Through differentiated CAE analysis services such as injection molding analysis and structural analysis,

we seek to provide optimal product design for our plastic materials and propose a structurally secure design.

Providing solutions through injection molding analysis at each step.

Please swipe horizontally

to view the content.

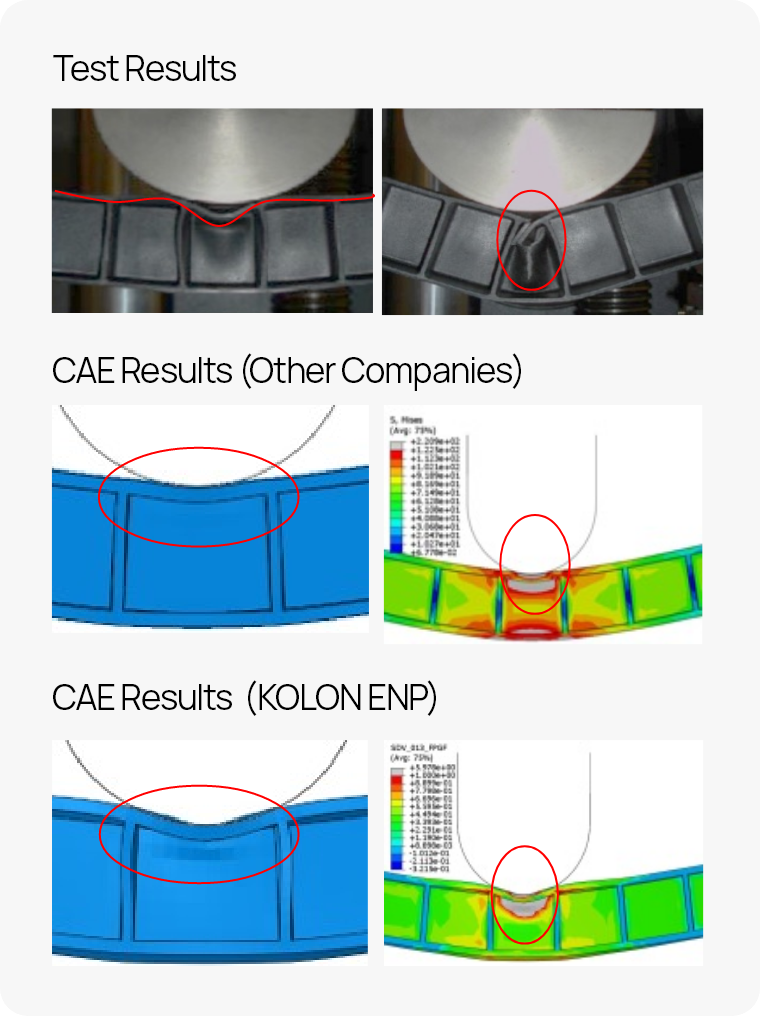

Providing CAE results and structural improvement solutions through static/dynamic analysis

Strength evaluation of products through static structural analysis

Evaluation of dynamic performance through collision test simulation

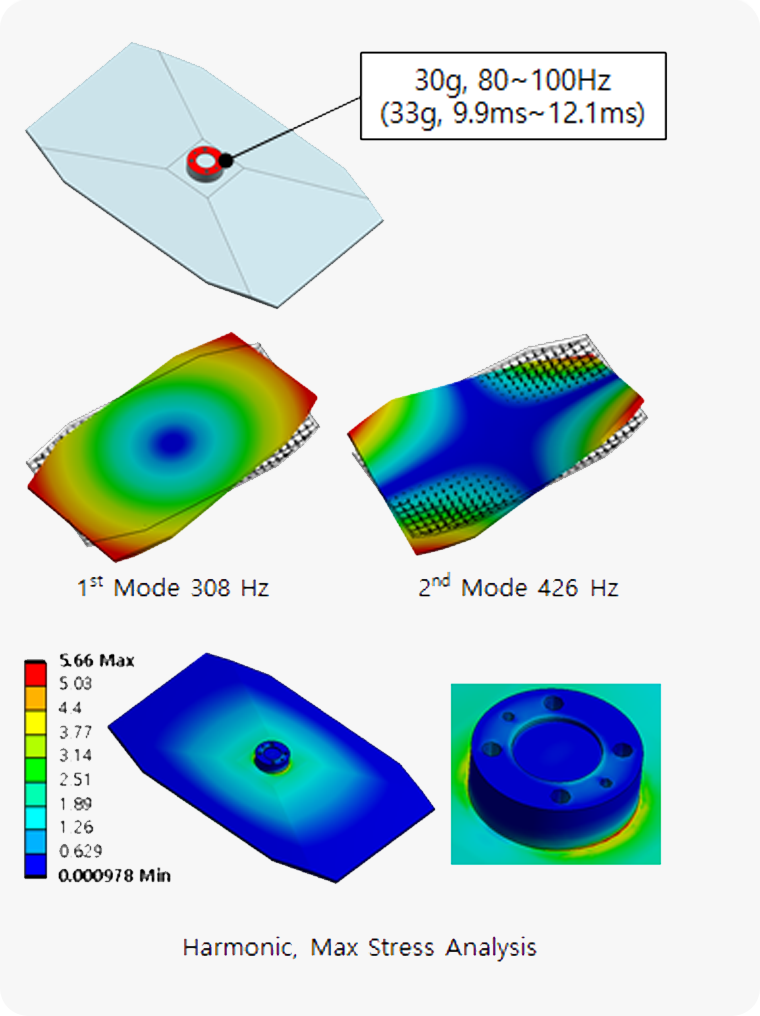

Analysis of vibration and noise reduction

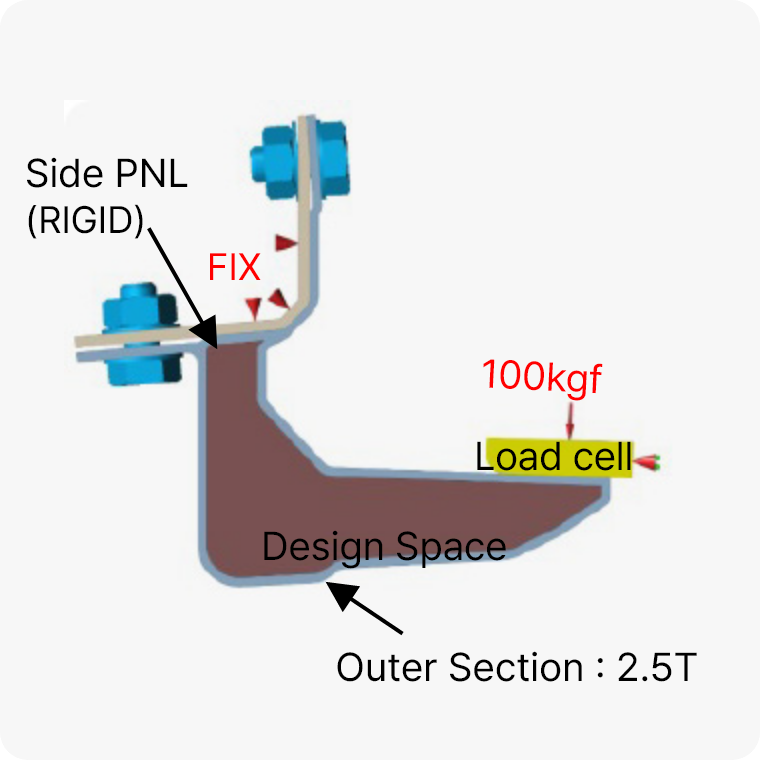

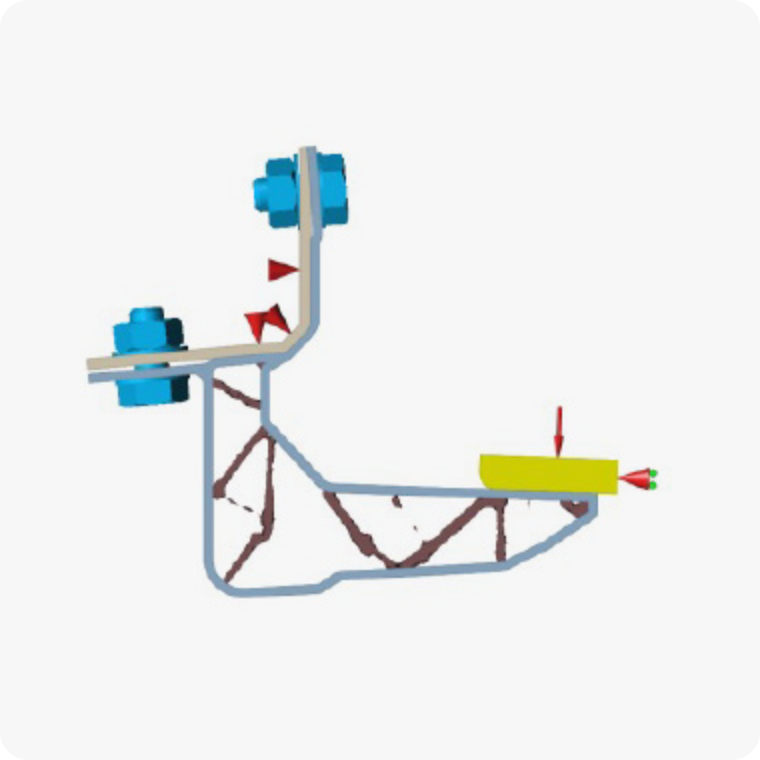

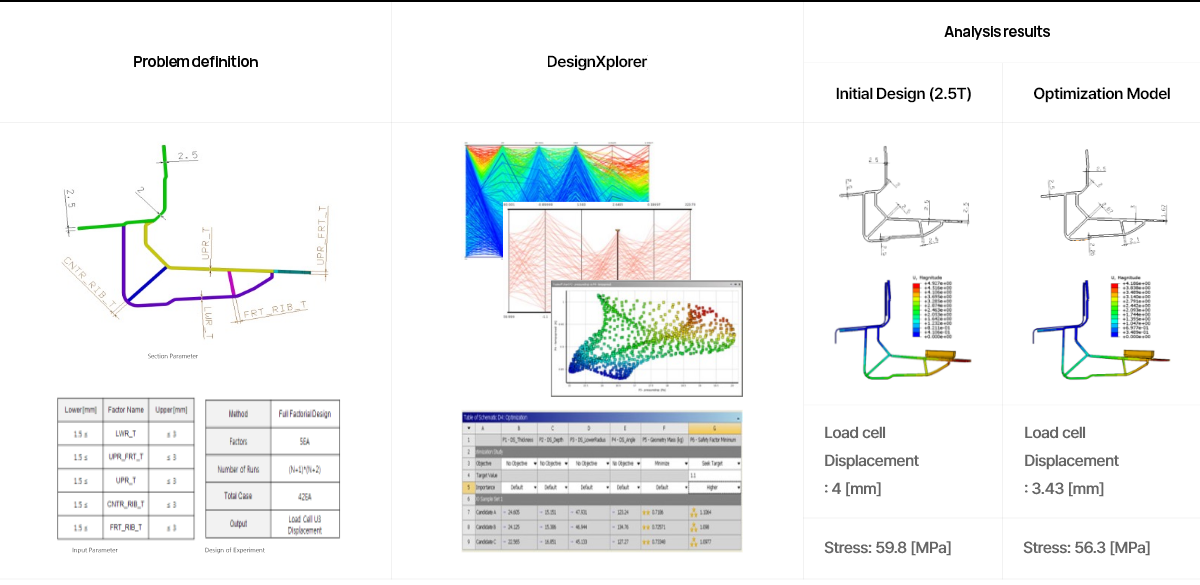

Creating effective designs using topology optimization without relying on experience, reducing repetitive redesign processes

Verification of material, shape, and load and analysis of various design variables

Proposing designs that maximize strength while minimizing weight (cost savings through weight reduction possible)

Problem definition (material, load, design, etc.)

Shape optimization

Final design proposal considering manufacturing

Once the analysis for design optimization is completed, sensitivity to the each dimensions is identified and optimization is performed.

Please swipe horizontally

to view the content.

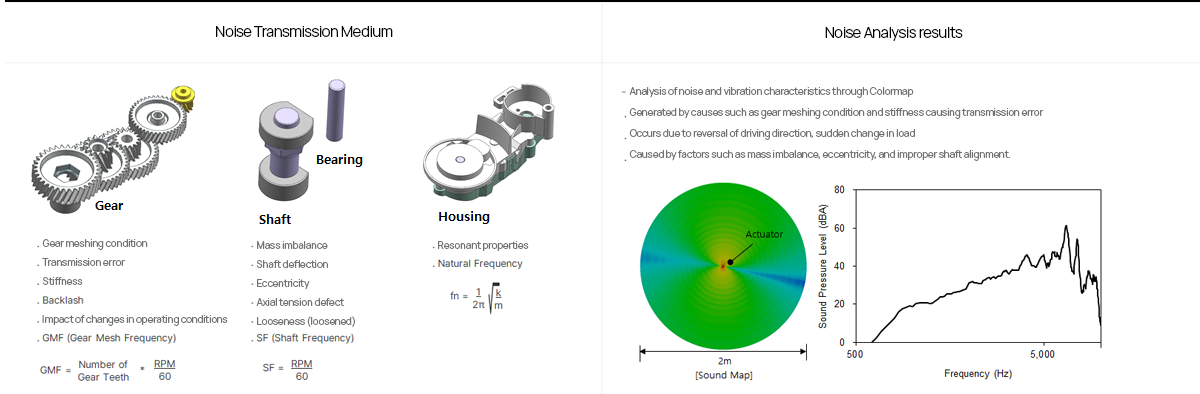

NVH(Noise, Vibration, Harshness) Analysis

The reason of noise : caused by solid mechanical linear wave equations

Please swipe horizontally

to view the content.